CBM – Condition Based Maintenance Implementation

The condition-based maintenance (CBM) is a maintenance strategy based on information about machine condition.

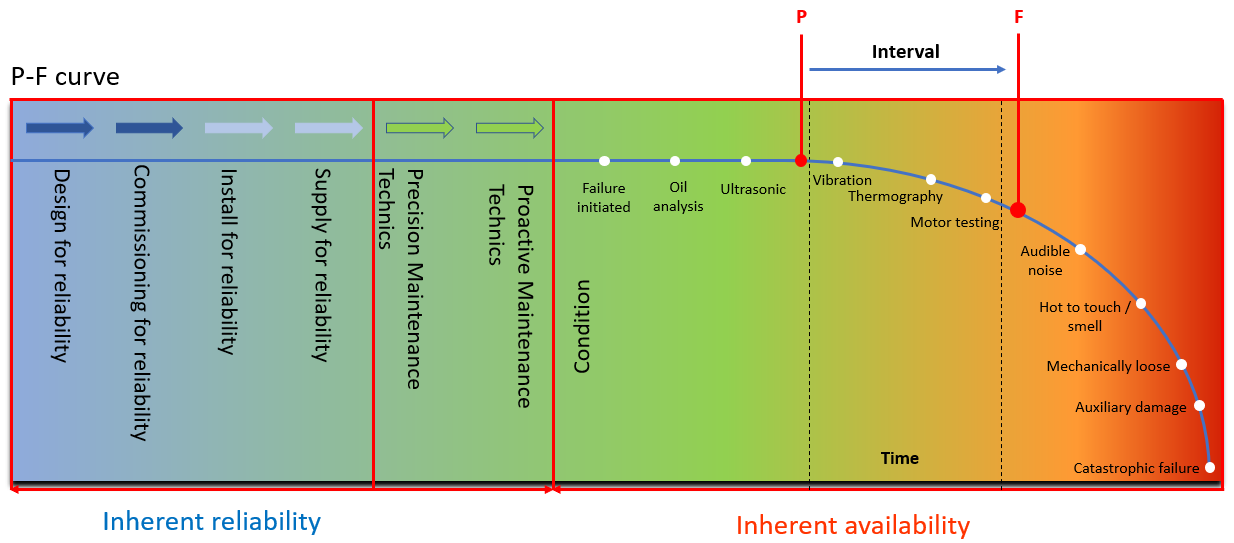

The machine condition is influenced by many factors as it is showed below in the P-F curve.

The P-F curve is a graph that helps visualize an asset’s condition to determine its practical lifespan.

Ludan engineering based on his expertise for design, installation and equipment operation supports clients to choose the proper maintenance management strategy.

Our experts are certified for different reliability technics and collaborates with the engineering departments to improve equipment performance.

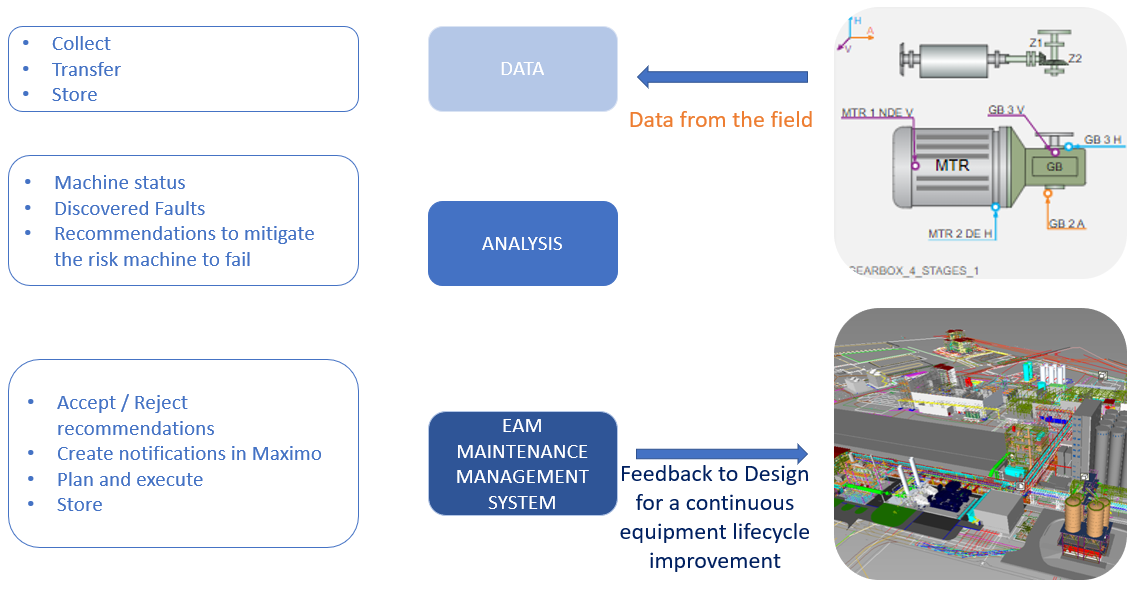

Our CBM solution combine the reliability know how and modern tools for enterprise asset management. An equipment is evaluated starting with his role in the process and continue with the operation condition. The reliability technics are used to evaluate the condition machine and the result is used as input for asset management.

With our solution for CBM, each equipment has his own model for analysis and historical data like: performance, cost, failure, efficiency.

In the below picture is presented an sample of how vibration technic is implemented at the equipment level and how is communicating with the EAM to improve the work management.